「秩父銘仙:新啓織物 ほぐし織り」Chichibu Meisen Hogushi Weaving

(Continuing from my previous article about Chichibu Meisen Museum & Nassen dyeing.)

秩父銘仙や捺染の続きです。

If you have read my introduction of Meisen and Nassen dyeing you might be curious now what would happen to those silk threads after they got their lovely design and colour?

To find out we visited Arakei Orimono a small traditional family owned factory workshop in Chichibu, Saitama who kindly opened their doors for us.

この前、秩父銘仙館や捺染体験について書きました(英語だけですが・・)。

銘仙って、絹の糸を染めるだけで終わらないので、その続きも紹介したいと思って、本織りの工房まで行ってきました。

秩父で現在も伝統を引き継ぐ「新啓織物」さんに工場を見せて頂きました。

Mr. Arai’s father started his business 45 years ago – when the industry was already in danger and other factories started closing down their business. He was the last one to start in the Meisen business and his son, Mr. Arai took over this business about 10 years ago.

銘仙の仕事は少なくなった45年前、今の新啓織物さんのオーナーである新井さんのお父様がこの会社を新しく立ち上げました。そして10年前、新井さんはこのお仕事を引き継いだそうです。

As present four family members work in this work shop: Mr. Arai and his wife as well as the father and his wife. (The old lady is called the lovely name “orihime” which translates as “weaving princess”. That’s so adorable!)

現在、家族の4名(新井さんのご両親、新井さんと妻)で頑張りながら銘仙を織っています。(お母様は私たちが訪問したときに、ご丁寧に挨拶してくださったとても可愛い方です。)

“As introduced by Arakei Orimono, the weaving technique “Hogushi” was invented in the early 20th century in Chichibu. It became trendy and fashionable as a fabric of a daily-wear Kimono, with its modern and stylish patterns, during the Taisho to early Showa era.

The technique, with patterns printed on the warp before weaving, is difficult to achieve by machine. Therefore, the pattern is still printed diligently by hand by craftsmen and the fabric is woven on a traditional wooden loom.Although the number of craftsmen is only few at present, Arakei Orimono strives to maintain and promote this traditional technique, introducing many people to its charm.”

「銘仙と技法について

江戸時代から絹織物の産地として栄えた秩父地方。

銘仙とは、この周辺地方で織られた先染めの平織りの絹織物を総称します。

銘仙を代表する柄銘仙は「ほぐし織」という技法で織られています。経糸に型染めをする為、大胆な大柄を表現する事ができます

軽く着心地の良いこの布には表裏がありません。経糸の模様が緯糸の色と重なり合い深みのある色調が特徴です。」

A peek inside the workshop reveals many traditional machines.

伝統的な機械がたくさん並んでます。

Meisen fabricants are still using the old weaving chairs from the Taisho period. The only difference is that they are now mechanically powered and moved by a motor connected to the loom chair via a large belt.

銘仙作りに使われている機織り機は大正時代に開発されたものです。ただし、人力だった昔と違って現在はベルトでモーターと繋げ動かしています。

Here can see the silk threads in the back of the loom chair reaching through small blade like guides into the front where the shuttle with thread will shoot through with high speed. Each line of warp will be pushed together tightly before the shuttle flies through again and adds more.

後ろから糸をセットして、前の方に杼が右左に見えない程のスピードで動いてます。筬は手前に引くことで左右に通した緯糸を経糸にしっかり織り込ませます。

I added a short video where you can see an old weaving chair in action.

Standing right next to it is so exciting it gave me goosebumps! Also it is rather loud!

機織り機の動画を撮りました。動いてる瞬間、側に立つと鳥肌がでた!嬉しくてワクワクしました。(笑)

One person would observe and work on several loom chairs at the same time. It is crucial to refill the warp in the shuttle before they run out.

We learned that Winter is actually not the best time for weaving as the air is too dry and the silk threads tend to rip easier. If that happens, the fabric bolts design could be ruined and become unusable.

In Summer the air has a high humidity (which isn’t a fun work environment) but the silk can be woven more neatly and hassle free.

大変な作業ですが、一人でいくつもの機織り機を動かします。織りながら調節や杼の糸を足す仕事は大事です。

冬の季節は乾燥してるので、糸は切れやすいとのことで湿気のある夏の方が織りやすいと教えて頂きました。(工場は大変暑そうですが・・)

Such loom chairs are not being produced anymore so the family has to repair and fix the machines themselves somehow with old spare parts or self-build solutions.

銘仙用の機織り機は現在生産されていませんので、修理は買い溜めしてある昔の交換部品を使います。それがなければ自分で作るしかありません。

Arakei is one of very few weavers left who actually make fabric for kimono. Many other companies already specialised into only making smaller items like fabric for shawls, bags etc. however they are still making fabric bolts for Meisen kimono.

They design themselves and also added a nassen dyeing studio to their production to be able to do small lot projects by themselves.

殆どのメーカーは小物用の生地しか作らない中、新啓織物さんはまだ着物用の反物も作っています。自分でもデザインしたり、最近は工房を少し広めて、小ロットの捺染もできるようになりました。染めの技術者が減っていく中、なんとか染めの技術を残していきたいと考えているからだそうです。

Usually dyeing and weaving are two strictly separated areas and they work together with a dye business to traditionally colour the weave, however modern times call for adjustment of those traditions.

普段、染めと織りは全く別の技術で他の会社に染めてもらいますが、今の時代ですと少しやり方を変えないとうまくいけないと思います。

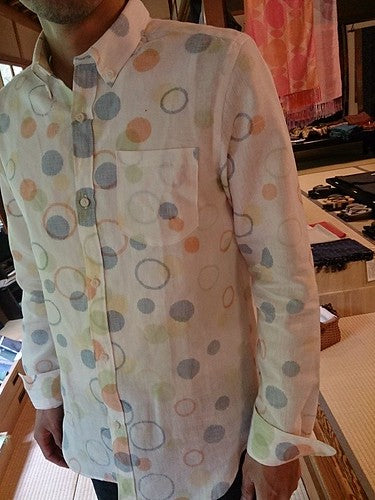

Lets look at some of their lovely pieces. They have been featured in various Japanese magazines over the past years.

さて、出来上がった商品を少しみましょう。色々な雑誌や新聞で新啓さんの商品が見られます。

Wow a cotton shirt from Meisen? That’s so lovely!

綿で仕上がった銘仙のシャツ? 素敵!

Arakei has a show room where they hold some open events sometimes where you could purchase the fabric bolts for kimono or bags and shawls directly. (It is quite far and not easy to reach without a car though.)

Arakei Orimono’s fabric also sells at pop up shops and in major shopping malls kimono shops in Tokyo and elsewhere.

新啓さんのショールームもあります。年に数回、小さなイベントが開かれ、お買い物ができます。

デパートの着物屋さんや展示会でも商品を手に取れるみたいです。情報は新啓さんのホームページからご確認お願いします。

☆ ☆ ☆

Details & Contact:

新啓織物 (Arakei Orimono)

Address: 〒368-0022 埼玉県秩父市中宮地町37−9

Phone: 0494-22-3140

Web: www.arakei.com

They also have a Facebook page, so show them some love:

フェースブックもあります:

www.facebook.com/arakei.orimono/

Thanks so much for reading!

ここまで読んで頂いてありがとうございました。

I always feel very sad when thinking about all those old traditions and its art dying out, so I hope we can find a way to embrace and bring back the Meisen industry to a healthy level.

Meisen to the world!

日本の伝統的な技術が無くなるのはとても悲しく、もっと国内外に発信したいと思っています。そして銘仙の技術がまた元気になる為、何かできないのかな〜と思っています。

銘仙を世界へ!♡

Anji

P.S.: 新啓さん、お忙しい中お時間ありがとうございました。